Service: +86-13485189165

Customize Various: Crucible,Boat,Dish,Mould,Heating Unit,Casting Dies,Tube,Ring,Lauder, Densener,

Rod, Plate, Block,Round

During aluminum and aluminum alloy smelting, hydrogen produced by chemical action with steam diffuse in molten aluminum, which will cause inner structural defect to aluminum products. In order to avoid such defect, most aluminum plants apply dissolved gas floating method to purify molten aluminum. i.e. inert gases such as nitrogen, argon is injected into molten aluminum, and hydrogen will be brought to molten aluminum surface with spread and rise of inert gas.

Rotor and shaft set is necessary to inject inert gas and stir for degassing regarding both intermittent and continuous online degassing methods.Because of properties of heat-resistance, antioxidation, high strength and non- infiltration, graphite becomes the optimal choice for material of rotor and shaft, which is named graphite rotor/impeller and shaft set.

Advantages of Kingwell Graphite Rotor and Shaft:

■ Impregnation Anti-oxidation Treatment. To extend service life of graphite rotor and shaft, Kingwell Carbon proprietary technology and nanometer anti-oxidant are applied to fill pores of graphite material and cover surface of graphite rotor and shaft, which improves properties of heat-resistance, anti-oxidation and anti-scour.

■ Coating anti-oxidation Treatment. Kingwell Carbon proprietary coating material is applied to already impregnated anti-oxidation graphite rotor and shaft except screw threads. The coating material is non-infiltrated with aluminum, but well adhered to graphite material.Because the coating material is heat-resisting, anti-oxidation, anti-corrosion and antiscouring the graphite rotor and shaft after further coating treatment has much longer lifespan.

■ Partial strengthening Method. According to endusers' application situation, we are capable to strengthen the most easily consumed part to get the longest service life for graphite rotor and shaft at the lowest cost.

Kingwell Carbon graphite rotor and shaft service life is around triple of similar graphite rotor and shaft in Chinese market.

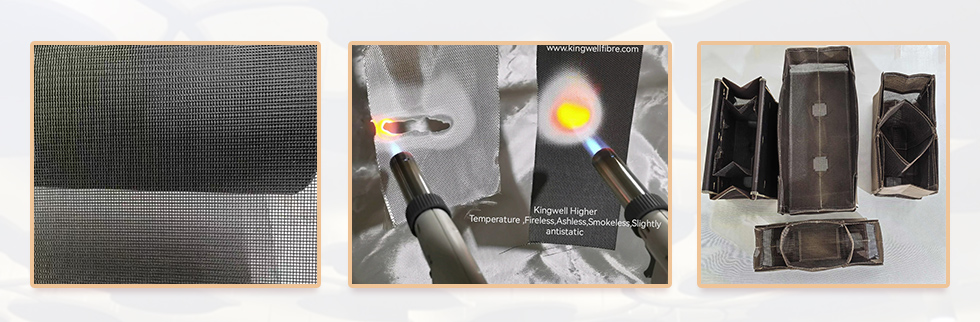

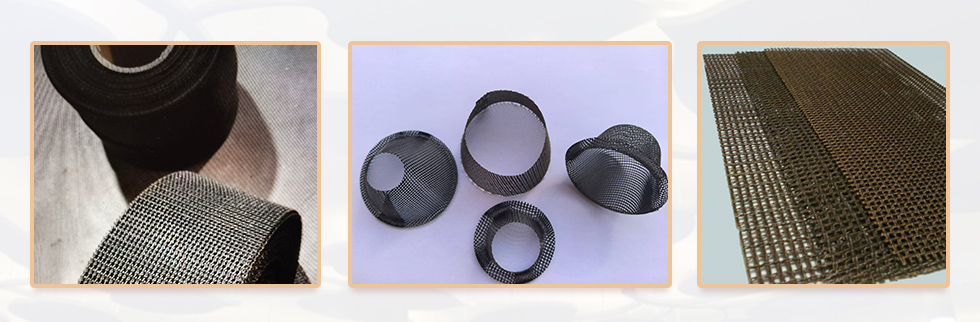

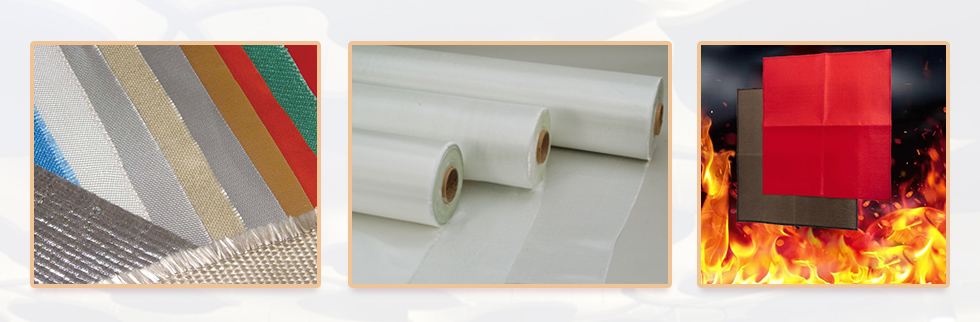

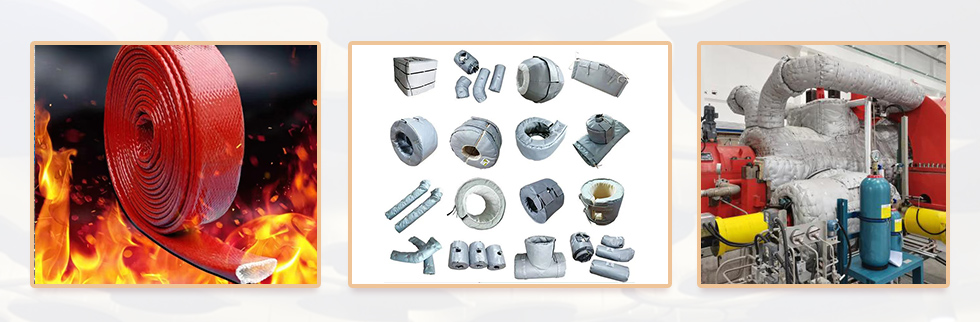

Main Products :Combo bag,Filtration,Filter,Fire Blanket, Fiberglass,Basalt,Silica,Ceramic,Carbon,PTFE,Graphite,Aerogel,Insulation

Main Products :Combo bag,Filtration,Filter,Fire Blanket, Fiberglass,Basalt,Silica,Ceramic,Carbon,PTFE,Graphite,Aerogel,Insulation