Service: +86-13485189165

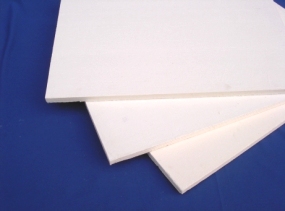

Vacuum Formed Ceramic Fiber Board

High Temperature Alumina Fiber Board ................................ up to 1800°C

Bio-Soluble Fiber Board...................................................up to 1100°C

Vacuum Formed Ceramic Fiber Board

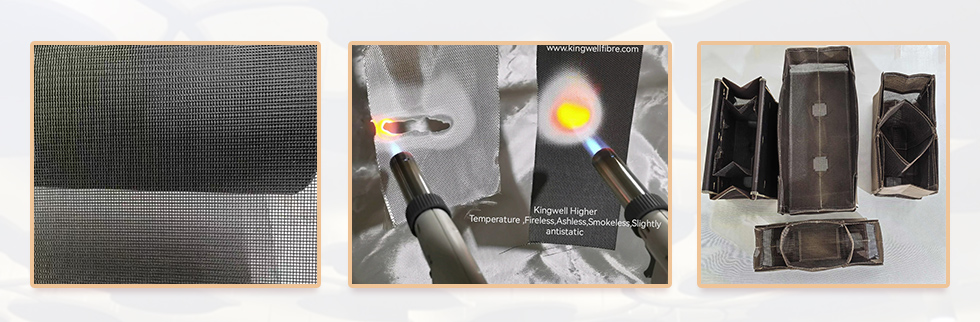

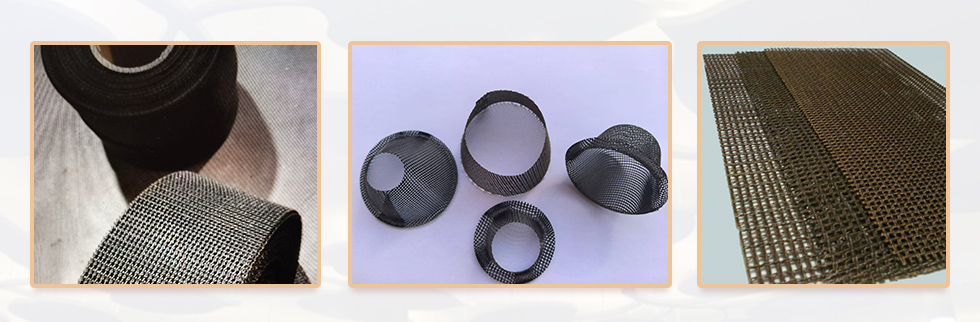

Kingwell boards are high performance insulation products manufactured from ceramic fiber (or with alumina fiber) and binders, with Kingwell unique shot removing and vacuum forming process, provide excellent high temperature stability, extra low thermal conductivity, high compressive strength.

Kingwell boards can be easy to saw, drill and die-cut, used as hot-face or back-up thermal insulation in various high temperature applications in furnaces, kilns etc. Additional hardness and strength can be reached with post treatments. Available in variety of compositions, densities, sizes and post treatments combinations, Kingwell board is one of the most versatile products available to the industry today.

Classification Temperature 1260°C, 1400°C, 1430°C, 1500°C, 1600°C

Density: 280-650kg/m3

Advantages

► High temperature stability

► Low thermal conductivity

► Low heat storage

► Non-wetting to molten aluminium

► Good flexural and compressive strength

► Close tolerance with excellent surface finish

► Easy to cut, drill or saw

Availabilities

► Thickness: 5-125mm

► Dimension: 900 x 600mm, 1000 x 600mm, 1200 x 1000mm

Post Treatments

► Dried Normal

► Surface hardened

► Completely hardened

► Fired

► Fired and surface hardened

► Fired and completely hardened

Applications

► Furnace linings

► Kiln furniture

► Hot gas duct linings

► Refractory backup insulation

► Launder insulation

► General molten metal contact

► Fire protection systems

► Glass tank side and wall insulation

► Expansion joint material

► Combustion chamber insulation

► High temperature gasket and seals

High Temperature Alumina Fiber Boards

Kingwell high temperature boards are rigid and self-supporting, made from alumina fiber, with Kingwell’s unique forming technology and treatment process, offer exceptional high temperature stability, low thermal conductivity at elevated temperature. Available in various compositions, densities and sizes, additional hardness and strength can be reached with post treatments.

Application Temperature 1700°C, 1750°C, 1800°C

Density: 350-550kg/m3

Advantages

► Exceptional thermal stability

► Low thermal conductivity

► Low heat storage

► Good flexural and compressive strength

► Close tolerance with excellent surface finish

► Easy to cut, drill or saw

Availabilities

► Thickness: 25-125mm

► Dimension: 900 x 600mm

Post Treatments

► Fired

► Fired and surface hardened

► Fired and completely hardened

Applications

► High temperature furnace linings

► Kiln furniture

► Combustion chamber insulation

Bio Soluble Fiber Board

Kingwell Bio Soluble Fiber Board is manufactured from unique vitreous fiber which has very high solubility in body fluids, hence has no hazard classification. With Kingwell's advanced vacuum forming technology, Kingwell Bio Soluble fiber board provides excellent thermal insulation and high compressive strength.

The boards can be easy to saw, drill and die-cut, additional hardness and strength can be reached with post treatments.

Classification Temperature 1100°C

Density: 300kg/m3

Advantages

► Low shot content

► Environmental friendly

► Low thermal conductivity

► Resistance to high temperature

► Good flexural and compressive strength

► Close tolerance with excellent surface finish

► Easy to cut, drill or saw

Availabilities

► Thickness: 5-125mm

► Dimension: 900 x 600mm, 1000 x 600mm, 1200 x 1000mm

Post Treatments

► Dried Normal

► Surface hardened

► Completely hardened

► Fired

► Fired and surface hardened

► Fired and completely hardened

Applications

► Boiler insulation

► Chimney lining

► Fire protection

► Heater insulation

► Wood burning stove

► Domestic cooker insulation

► Fire door infill

► Hot gas duct linings

► Launder insulation

► Fire protection systems

► Expansion joint material

Main Products :Combo bag,Filtration,Filter,Fire Blanket, Fiberglass,Basalt,Silica,Ceramic,Carbon,PTFE,Graphite,Aerogel,Insulation

Main Products :Combo bag,Filtration,Filter,Fire Blanket, Fiberglass,Basalt,Silica,Ceramic,Carbon,PTFE,Graphite,Aerogel,Insulation