Service: +86-13485189165

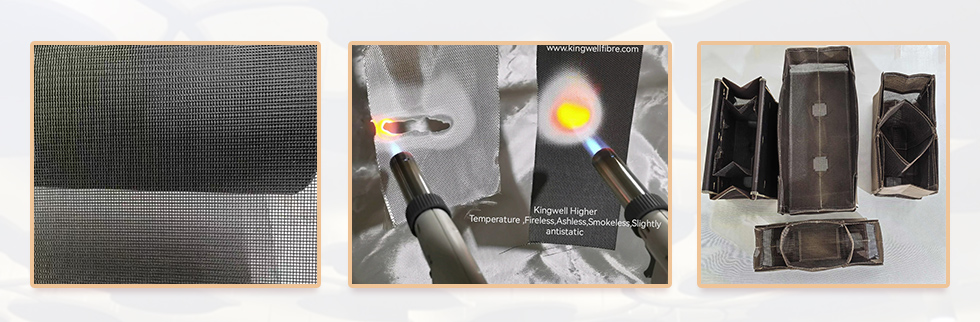

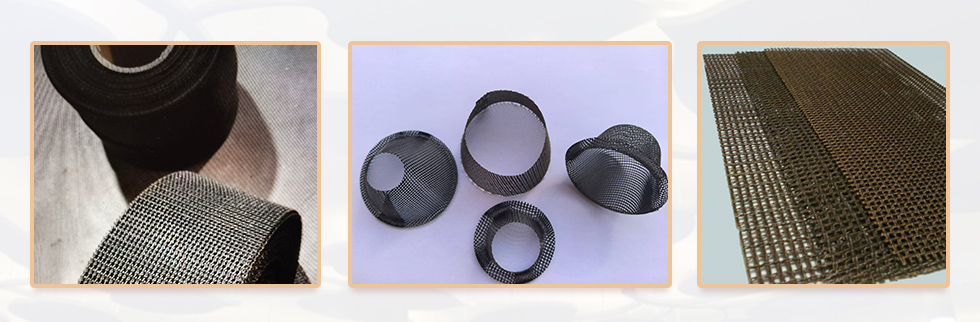

Kingwell Ceramic Fiber Paper is formed from ceramic fiber mixed along with binders, with high thermal capacity, excellent resistance to corrosion, good thermal resistance to shock, low thermal conductivity, good electric insulation, and good springiness. It can be used for thermal insulation, sealing, electric insulation, sound absorption, filtration etc instead of asbestos products as a kind of advanced light refractory material.

Features:

-Asbestos free

-White color,Good uniformity

-Long fiber, less shot

-High tensile strength

-Resistance to erosion

-Low thermal conductivity

-High electric insulation

-Good for die-cut and automatic stamping

Typical Applications:

-Thermal insulation, gasket, seal, separator, lining etc. for high temperature and chemical resistant applications

-Fire protection, spark and molten metal protection

-High temperature electrical insulation

-High temperature filtration

-Soundproof materials of auto

Serving Industries: Steel and metallurgy, Petro-chemistry, Automotive, Aerospace, Appliance, and many more.

P.S: We could customize variousflexibleorhardCeramic papers to meet customer’s specific request.

Specifications:

|

Description |

K-900 Paper |

K-1000 Paper |

K-1260 Paper |

K-1500 Paper |

|

Classification Temperature (C.deg) |

900 |

1000 |

1260 |

1500 |

|

Density (Kg/m3) |

210 |

210 |

210 |

210 |

|

Linear Shrinkage ( % ) (℃*24 h ) |

2.8(750) |

3.5 (850) |

3.0 (1100) |

3.2(1200) |

|

Rupture Strength (MPa) |

0.5 |

0.5 |

0.65 |

0.70 |

|

Organic Content (%) |

8 |

10 |

8 |

6 |

|

Thermal Conductivity Rate Kcal/mhC.deg(W/mK) , ASTM C201, 200kg/m3 |

||||

|

Average 400C.deg |

0.05 |

0.06 |

0.07 |

|

|

Average 600C.deg |

0.06 |

0.08 |

0.09 |

0.08 |

|

Average 800C.deg |

|

0.12 |

0.12 |

0.12 |

|

Average 800C.deg |

|

|

0.17 |

0.16 |

|

Chemical Composition (post-burnt): |

|

|

|

|

|

Al2O3 |

40 |

42 |

46 |

35 |

|

SiO2 |

56 |

54 |

50 |

44 |

|

ZrO2 |

|

|

|

15.5 |

|

Dimensions |

Thickness: 0.4, 0.5, 1.0, 2.0, 3.0, 4.0, 5.0,8.0 mm Width: 50~1270mm |

|||

|

Resoluble Ceramic fiber papers are also available to order. |

||||

Packings:

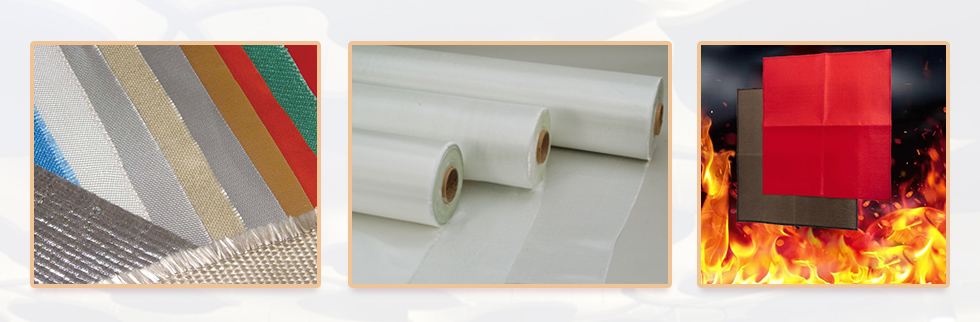

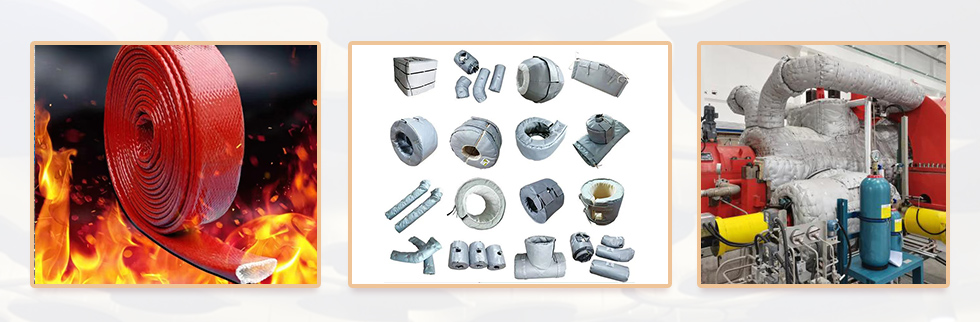

Main Products :Combo bag,Filtration,Filter,Fire Blanket, Fiberglass,Basalt,Silica,Ceramic,Carbon,PTFE,Graphite,Aerogel,Insulation

Main Products :Combo bag,Filtration,Filter,Fire Blanket, Fiberglass,Basalt,Silica,Ceramic,Carbon,PTFE,Graphite,Aerogel,Insulation