Service: +86-13485189165

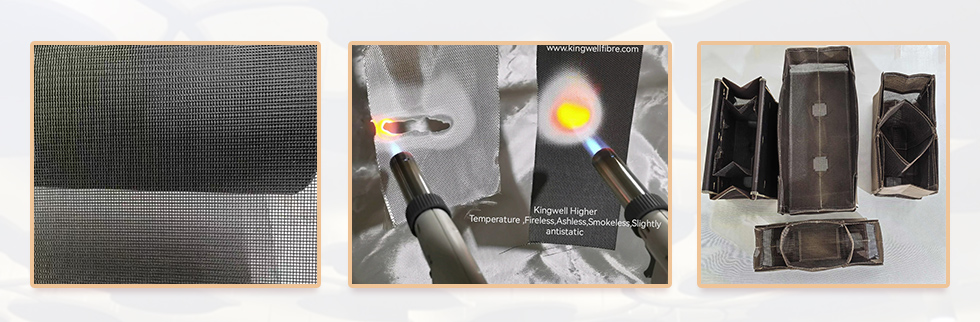

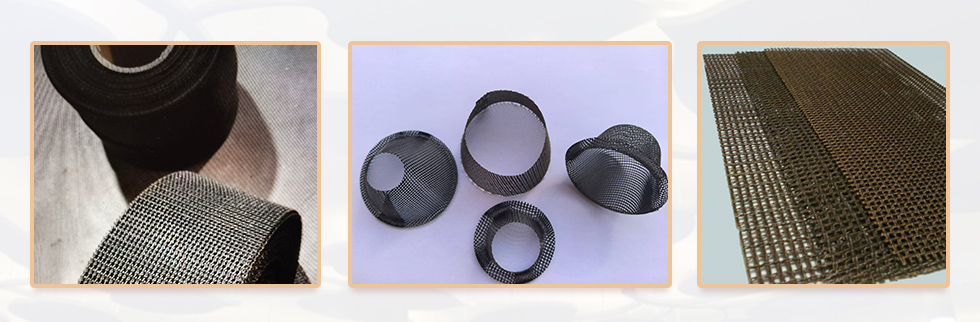

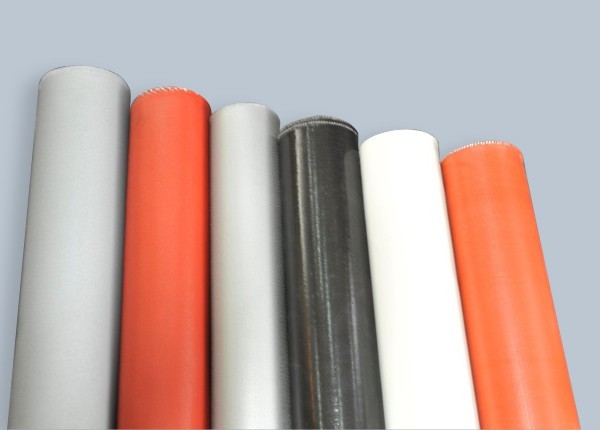

Kingwell silicone coated fabrics are conformable, flexible and wear resistant, they are constructed from woven fiberglass fabric that has been coated on one or both sides with silicone rubber.

They features excellent electrical insulation, high temperature insulation and chemical corrosion resistance.

Performances:

Materials for -70C.deg to 300C.deg Continuous Exposure and 550C.deg Short Duration Exposure.

--Ozone, oxide, light and weathering aging resistance, excellent weather ability used in outdoors and ages may be reached to 10 years.

--Good electric insulation: dielectric constant from 3 to 3.2 / breakdown voltage from 20 to 50 KV/mm.

--Excellent Chemical and Abrasion resistance.

Main Specifications:

|

Style |

Coating |

Weight (g/m2) |

Thickness (mm) |

Width (m) |

||

|

Base Fabric |

Coating |

Total |

||||

|

7628D200 |

Double sides |

200 |

200 |

400 |

0.35 |

1~2 |

|

3732S80 |

Single side |

430 |

80 |

510 |

0.5 |

|

|

3732D130 |

Double sides |

130 |

560 |

0.55 |

||

|

3734S100 |

Single side |

635 |

100 |

735 |

0.70 |

|

|

3734D200 |

Double sides |

200 |

835 |

0.80 |

||

|

3784S100 |

Single side |

850 |

100 |

950 |

0.9 |

|

|

3784D200 |

Double sides |

200 |

1050 |

1.0 |

||

|

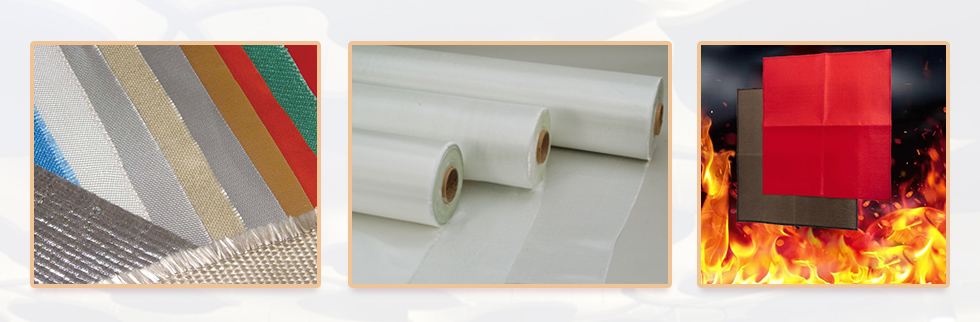

Colors: Grey, Red ,White, Black Customized specifications,colors and packages are available. |

||||||

Applications:

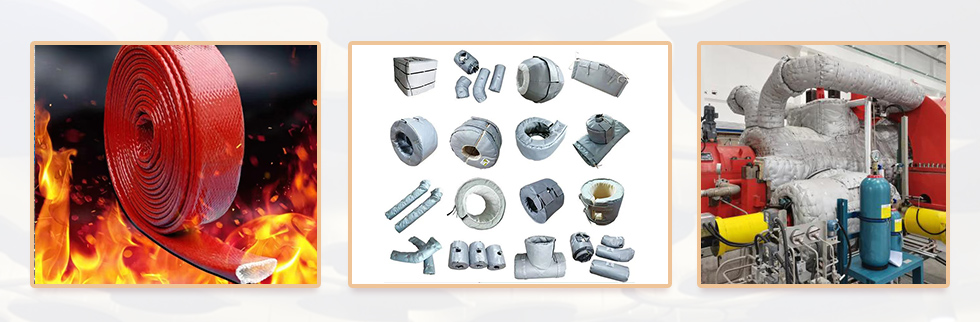

--Serve as welding blankets, heat protection quilt, foundry splash protection.

--Conveyor belt and expansion joints,flexible hoses.

-- Acoustic insulation of piping works, covers for equipment and personnel protection include: flange and valve covers, turbo covers, supercharger covers, muffler and silencer covers. exhaust system covers.

--Electrical insulation, chemical corrosion,UV light, abrasion and contamination resistance, packing material.

--Used for aerospace, marine, chemical industry, power plant, auto-manufacture, construction, piping flexility and sealing industry.

Main Products :Combo bag,Filtration,Filter,Fire Blanket, Fiberglass,Basalt,Silica,Ceramic,Carbon,PTFE,Graphite,Aerogel,Insulation

Main Products :Combo bag,Filtration,Filter,Fire Blanket, Fiberglass,Basalt,Silica,Ceramic,Carbon,PTFE,Graphite,Aerogel,Insulation