Service: +86-13485189165

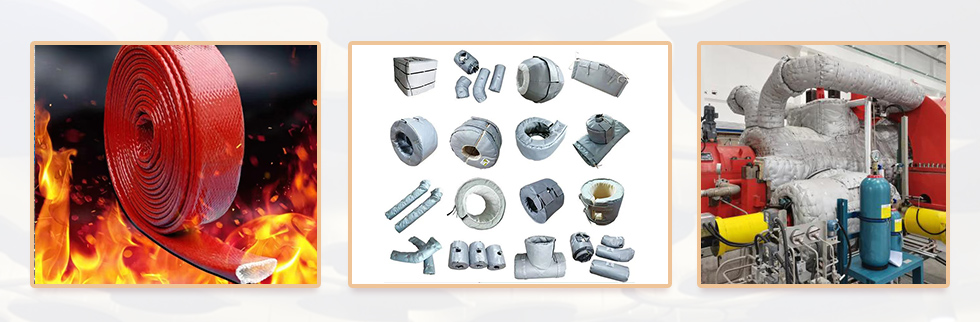

Aerogel Thermal Insulation Removable Blanket,Thermal Elbow PTFE Insulation Jacket, High Temperature Pipe Insulation Jacket ,Fiberglass Industrial Thermal Insulation Cover, Fiberglass Removable Thermal Insulation Covers for Cover Valves, Instrumentation Panels, Flanges & Pipeline

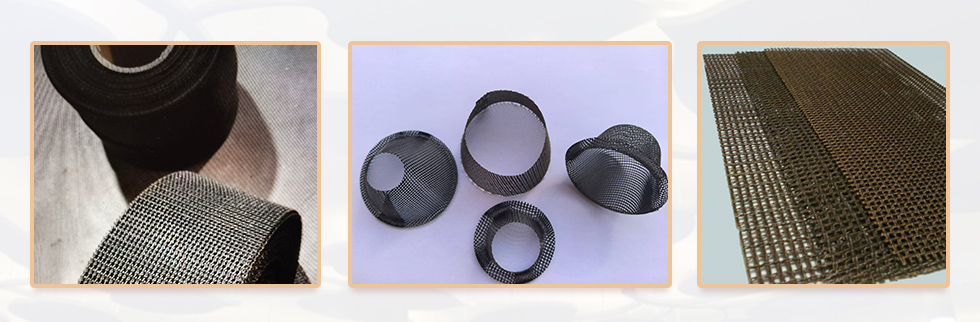

With the development of industrial technology, the traditional thermal insulation process can no longer fully meet the thermal insulation requirements of modern enterprise equipment.Removable insulation is also gradually replacing the traditional insulation process. So what is removable insulation? The detachable insulation is an independent insulation structure, which can be reused many times and has a long service life. Easy to install and disassemble. The shape of the detachable thermal insulation is designed according to the shape and structure of the equipment, so as to fit the equipment better. The insulation effect is more excellent. The detachable thermal insulation structure provides great convenience for installation and construction, making installation more convenient and construction period shorter, which can greatly save overhaul time, thereby improving equipment utilization and bringing better economic benefits to enterprises.

Removable Thermal Insulation Jacket Blankets are widely used in various kinds of equipments, machines, containers. They are great helpful to reduce heat transfer to consume less energy for machine working in the desired temperature.

Thermal Insulation Needs Analysis:

Size and Shape – We have standard sizing from 2-inch to 48-inch nominal pipe size, but can create a custom cover for nearly any shape or dimension.

Location of jacket – Will the jacket be indoors or outdoors? Is freezing an issue?

Temperature of the component being insulated – Does the component need to be kept cold? Or is the component hot? Will the insulation be subject to extreme heat?

Ambient room temperature – What is the current room temperature, and what is the desired room temperature?

Moisture – Is the area damp or subject to wet conditions? Is the component being insulated at risk for corrosion?

Jacket Weight –Is the component being insulated fragile, or is there any other reason a heavier jacket would be undesirable? Should we utilize several smaller jackets?

Noise Control – Is reduction of noise a desired outcome? Should we consider acoustic insulation?

Data Concerns – Does the client need to report energy savings to government agencies or for internal use? Does the client need a monitoring and alert system?

Main Applications:

Nowadays, Removable Thermal Insulation is a high grade pipeline heat preserving material and widely used in various pipeline, warm-ventilation air-conditioning equip of petroleum, chemical, filature,metallurgy, electricity, construction, kiln stove, paper-making, pharmacy, shipping, etc. it is suitable for various pipeline heat preserving and is an ideal pipeline heat preserving material. For example, pipeline, elbow, flange, valve, tie-in of pipeline, chemical reactor, equipment, air machine of fire power or nuclear power, instrument box and exchange equipment used in high temperature environment of steel factory, and other profiled part.

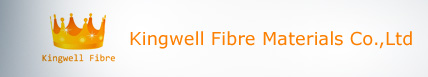

Two main products of Kingwell:

1, Inter temperature-hold type: keep the inter temperature of the protecter, by this to stop heat exchange of the inter and outside energy(convection, radiation, and transfer);

2, Resisting outside-radiation type: resist strong outside heat radiation to keep away the outside heat transfer to the inside which may impact the working temperature of the protecter and harm to the equipment, part, instrument.

Product Name

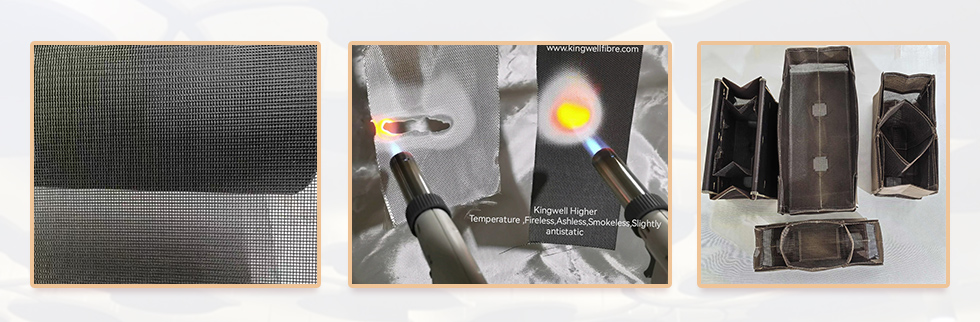

Reusable and Removable Thermal Insulation Jacket

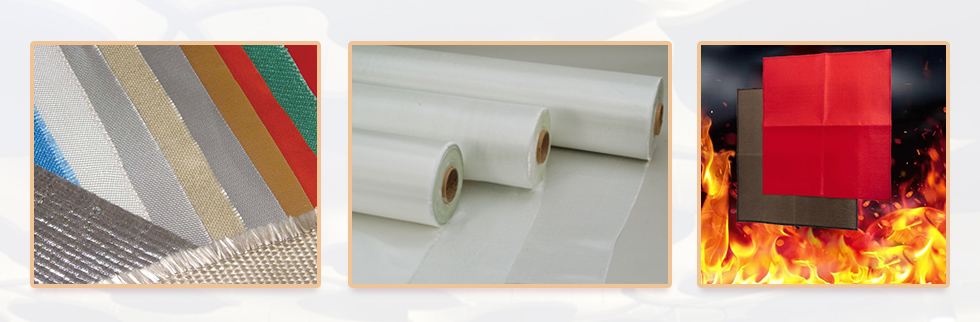

Base Material

High temperature fiberglass,Ceramic fiber

Regular Coatings

PTFE,Silicone, Aluminum Foil and etc.

Color

Silver,white,grey or Custom

Thickness

10-30mm or Custom

Weight

Custom

Functions

Save Energy,Heat Conservation, Heat Retention Maintenance, Noise Control ,Personal Protection, Working environment Improvement,Save Money

Application

Thermal insulation for pipes, valves ,Flanges

Steam traps

Barrel heaters on injection molding machine, extruder

Heater exchanger

Molds and dies

Exhaust Elbow

Turbines,Exhaust pipe of engine

Vessels,Manways,Panels,Pumps,Tanks

Any other applications needed to reduce heat loss

Temperature Resistance

-70 ºC-1200ºC

Standard

CE EN 1869:1997

Main Products :Combo bag,Filtration,Filter,Fire Blanket, Fiberglass,Basalt,Silica,Ceramic,Carbon,PTFE,Graphite,Aerogel,Insulation

Main Products :Combo bag,Filtration,Filter,Fire Blanket, Fiberglass,Basalt,Silica,Ceramic,Carbon,PTFE,Graphite,Aerogel,Insulation