Service: +86-13485189165

Silica aerogel is renowned as the lightest and lowest-density solid material known, at barely more than the density of air. Silica aerogel has a Porous, Sponge-like structure in which greater than 98 percent of its volume is empty space (air).

By comparison, silica aerogel is 1,000 times less dense than glass. Even though the silica aerogel is mostly Air, one of its remarkable features is that it can support more than 10,000 times its own weight. Silica aerogel can have a very large surface area within its bulk, ranging from 500 to 1500 square meters per gram, depending on its density.

Silica aerogel is also known for its low density, low thermal conductivity, low sound speed, low refractive index and high transparency

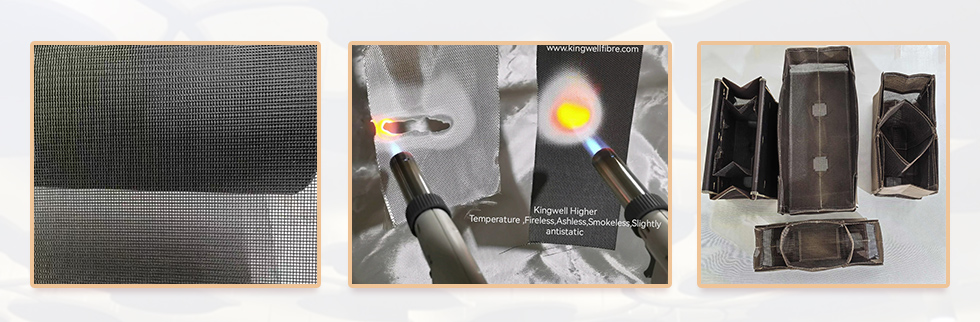

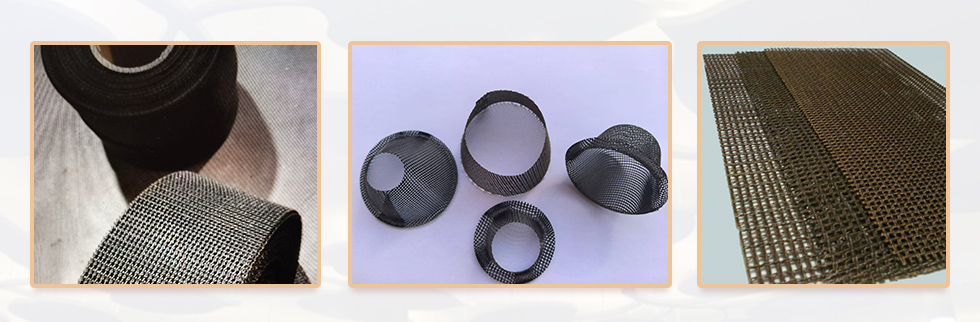

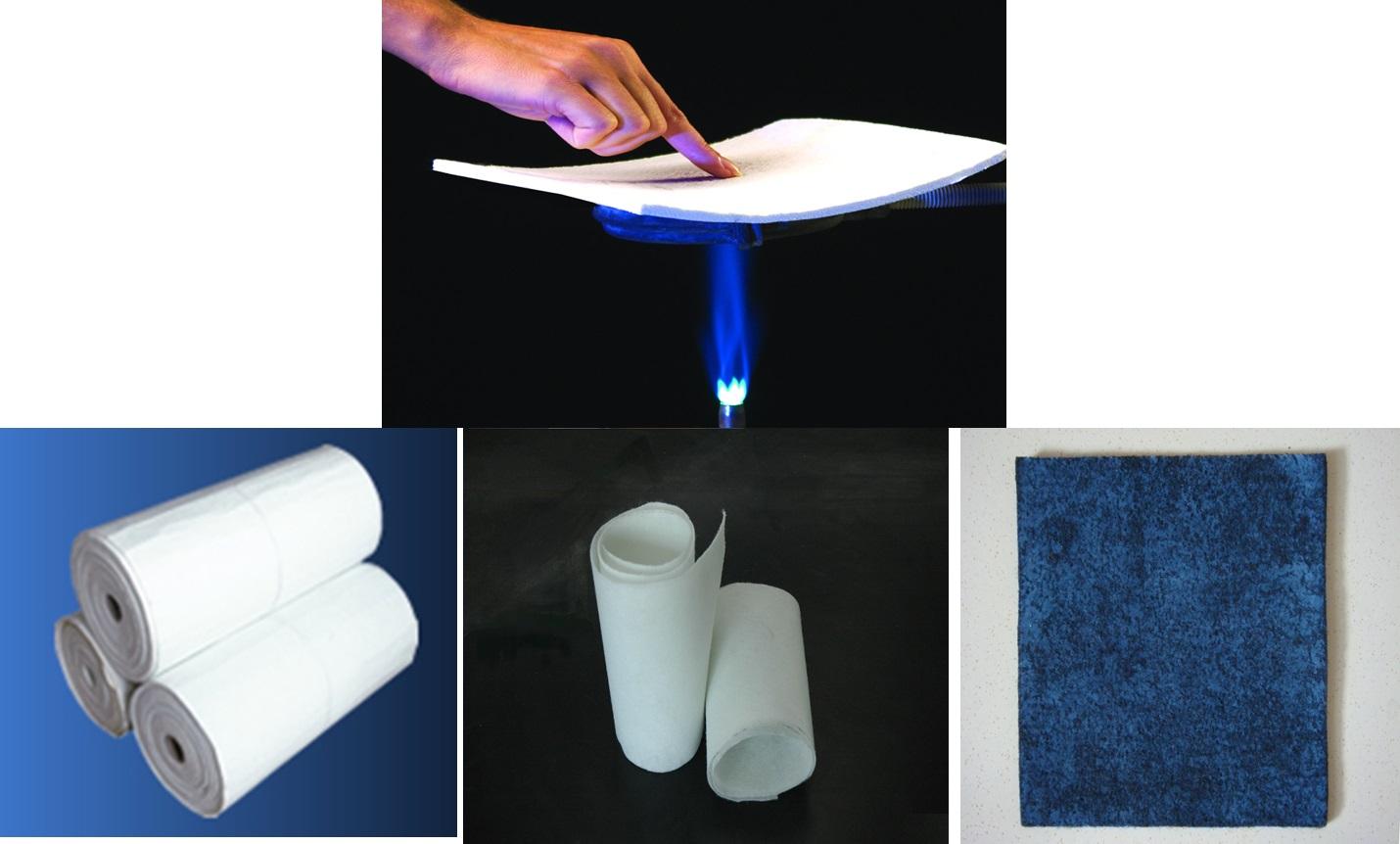

Silica Aerogel Thermal Insulation Blanket

It is nano-adiabatic , main body is mesoporous silica aerogels and Special inorganic fiber needle punching blankets.

It has excellent insulation property, surface hydrophobicity and flame retardant property. Its thermal conductivity coefficient at the normal temperature is about 0.016W(m.k), which is lower than still air.

And its hydrophobic rate can reach 99% under normal temperature. It also has excellent flame retardant performance, the fire rate meets the National Standard A1 level.

Wide service temperature: -200~780℃.

Easy to cut and install at construction site.

Products can be used for pipes, tanks, containers and other areas and it is the pursuit of efficient insulation and the best choice for the lowest energy consumptio :

thermal insulation, super capacitors, water deionizers, sensors for gas detection, pollution filters, dielectric coupling layers integrated circuits, absorbents for desiccation, insecticides, dangerous liquid storage vessels, catalysis, matching layers for acoustical transducers, sound insulation, kinetic energy absorbers, sound insulation, impact protection, crucibles for molten metals, nuclear particle detectors .

The unique combination of properties makes aerogels useful in a range of applications and best candidates for many others in the future.

|

Model |

SACB-0-3 |

SACB-0-6 |

SACB-0-10 |

|

Thickness(mm) |

3 |

6 |

10 |

|

Width(mm) |

1200/1400 |

||

|

Color |

White |

||

|

Service Temperature(°C) |

-200~650 |

||

|

Density |

200 ± 20 kg/m3 |

||

|

Linear Expansivity |

4.2x10-6 |

||

|

Hydrophobicity |

>99% According to GB/T 3810 |

||

|

Tensile Strength(min) Kpa |

100 Kpa According to GB/T 10299-2011 |

||

|

Dimensional stability(max) |

1% According to GB/T20285-2006 |

||

|

Burning behavior class |

S4 According to GB/T20285-2006 |

||

|

Tensile Strength(min) Kpa |

100 Kpa According to GB/T 10299-2011 |

||

|

Coefficient of Thermal Conduction (W/mK) |

-200℃ |

0.011 |

Test method YB/T 4130-2005 |

|

-100℃ |

0.012 |

||

|

0℃ |

0.014 |

||

|

100℃ |

0.018 |

||

|

200℃ |

0.021 |

||

|

300℃ |

0.025 |

||

|

400℃ |

0.032 |

||

|

500℃ |

0.038 |

||

|

600℃ |

0.046 |

||

|

Application |

Petroleum, Chemical Industry, Electric Power etc. in the Pipeline and Equipment Insulation, can also be used in Aeronautics and Astronautics Fields. |

||

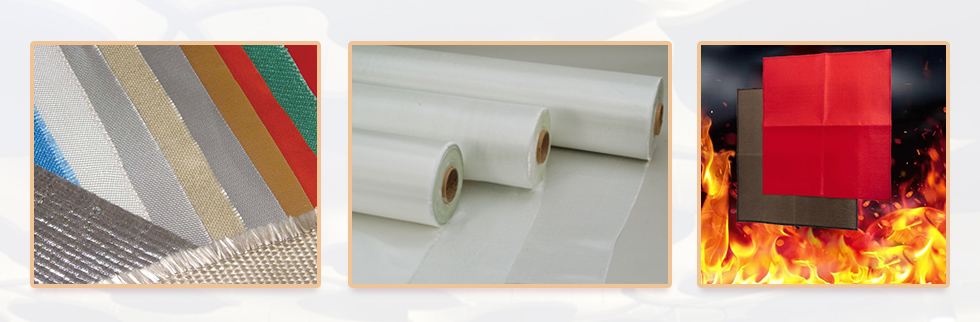

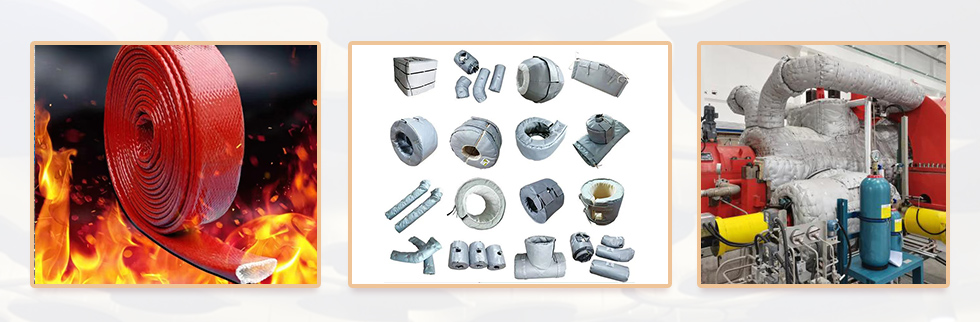

Main Products :Combo bag,Filtration,Filter,Fire Blanket, Fiberglass,Basalt,Silica,Ceramic,Carbon,PTFE,Graphite,Aerogel,Insulation

Main Products :Combo bag,Filtration,Filter,Fire Blanket, Fiberglass,Basalt,Silica,Ceramic,Carbon,PTFE,Graphite,Aerogel,Insulation