Service: +86-13485189165

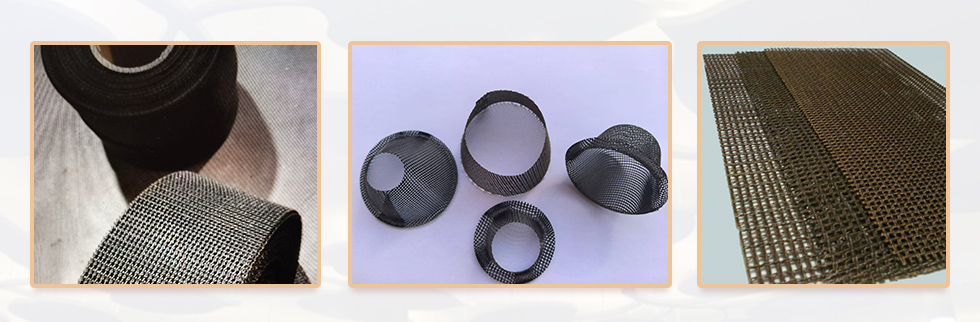

We Kingwell specialize in world-class high quality customized Combo Bags for molten metal Filtration and Distribution used for DC Sheet Ingot Casting & Slab Casting in any smelters.

Functionality of Combo Bags:

In Direct Chilling Casting, Combo Bag controls the Flow Pattern and Temperature Distribution,which effect the temperature profile across the mold and hence the molten metal sump, these have bearing on the structure in solidification. The practical solution to this problem has been to redirect the downward flow out of the downspout to a horizontal distributed flow,using a solid refractory box section or a flexible fiber bag, that is, Combo Bag. Distribution of hot metal into the ingot sump results in uniform temperature gradient.

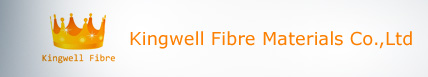

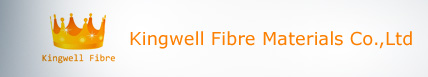

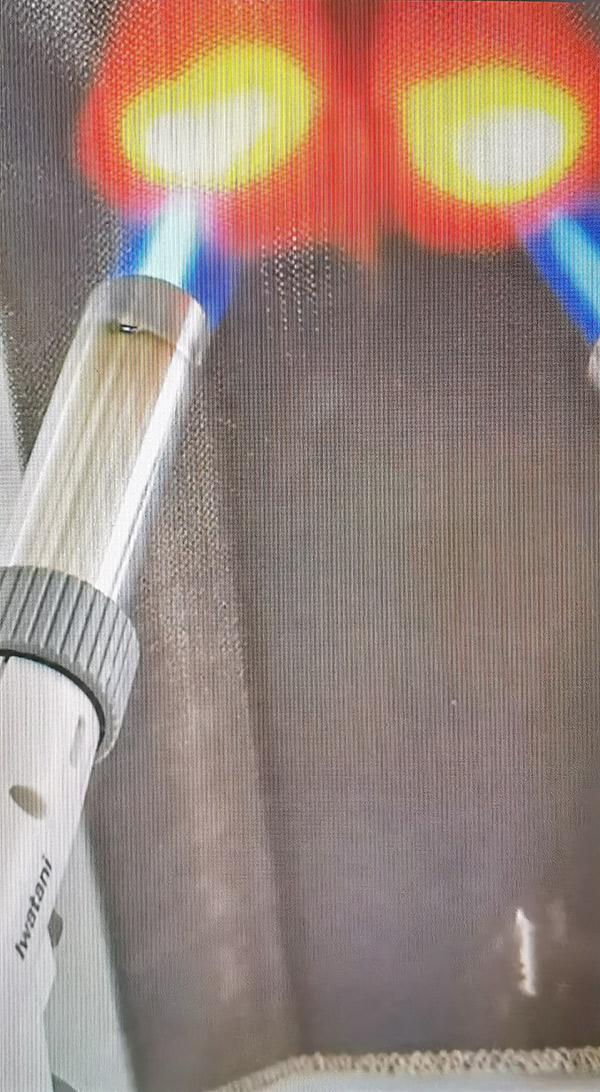

High Temp Resistance up to 1,200℃

Advantages of Kingwell HT-Rigid Combo:

•No Fire,No Black Ashes Pollution,No Offensive Toxic Gas,Smokeless,0 contamination to the Slab

Casting from A to Z

•Super corrosion resistance to molten aluminum,

Not easy to stick to the mold,

Beneficial for initial casting,and good casting effect, High safety

•Say No to risk of Fibre Combo bags easily fragile and broken for series of casting

•Improve the casting efficiency

•Good breathability, beneficial for reducing melt Turbulence, improve metal distribution

•Exquisite heat effect functions,the least heat loss,none overheating

•Extreme Tough throughout all the cast

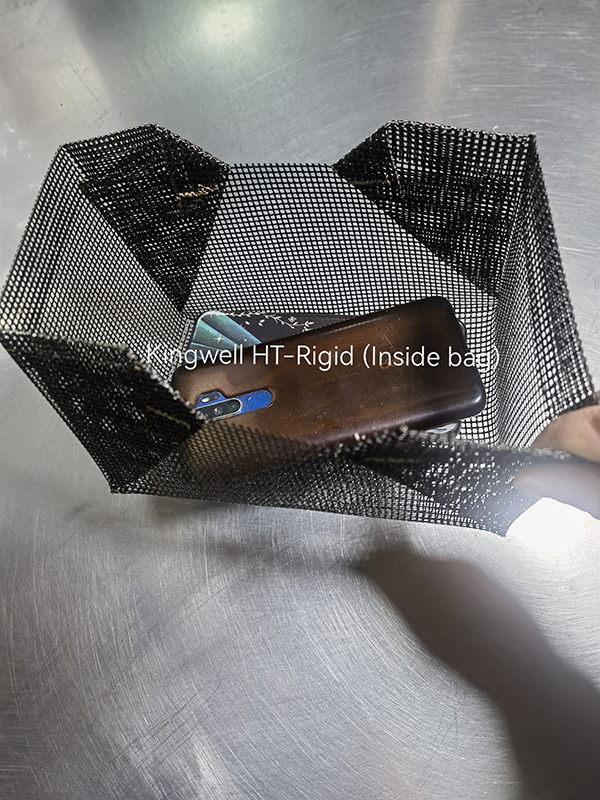

•The inside bag is fixed on the outside bag , No Displacement or Deviation during the casting process.

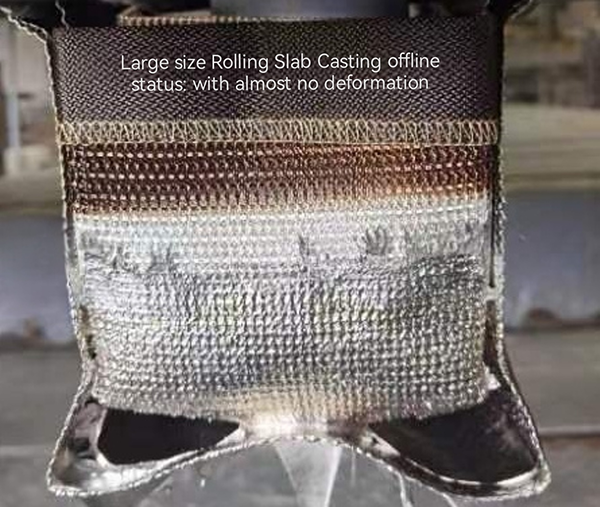

•Negligible Deformation

•The much less Shrinkage to other market qualified competitions

•To guarantee the Constant Throughflow and Unique Filtration Effectiveness

•To achieve the best molten metal Flow Pattern and Temperature Distribution

•These Combos are cost effective and yield higher Return on Investments

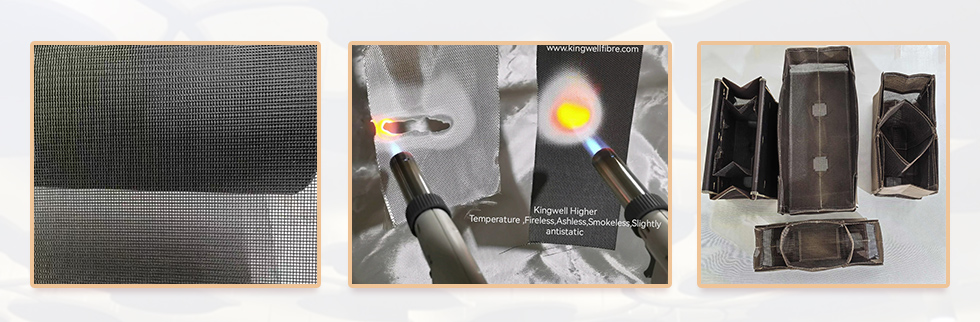

The above picture is shown Kingwell HT Combo bag offline statuses after large size casting.

Main Products :Combo bag,Filtration,Filter,Fire Blanket, Fiberglass,Basalt,Silica,Ceramic,Carbon,PTFE,Graphite,Aerogel,Insulation

Main Products :Combo bag,Filtration,Filter,Fire Blanket, Fiberglass,Basalt,Silica,Ceramic,Carbon,PTFE,Graphite,Aerogel,Insulation